Service Hotline

400 8392 001

Service Hotline

400 8392 001

Sulfur Meter Series

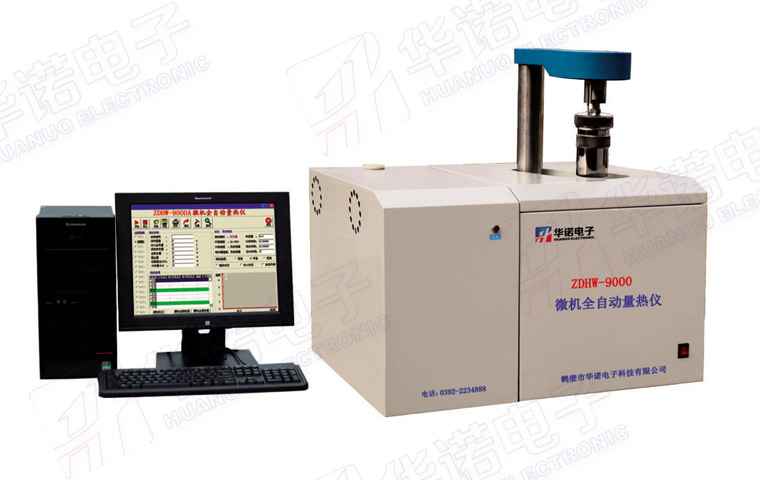

Calorimeter Series

Industrial analyzer series

Element analyzer series

Coal Ash Fusibility Test Series

Coke Testing Equipment Series

Coal active equipment

Gas detection tube series

Crushing Sampling Series

Sulfur Meter Series

Calorimeter Series

Industrial analyzer series

Element analyzer series

Coal Ash Fusibility Test Series

Coke Testing Equipment Series

Coal active equipment

Gas detection tube series

Crushing Sampling Series