Service Hotline

400 8392 001

Service Hotline

400 8392 001

Sulfur Meter Series

Calorimeter Series

Industrial analyzer series

Element analyzer series

Coal Ash Fusibility Test Series

Coke Testing Equipment Series

Coal active equipment

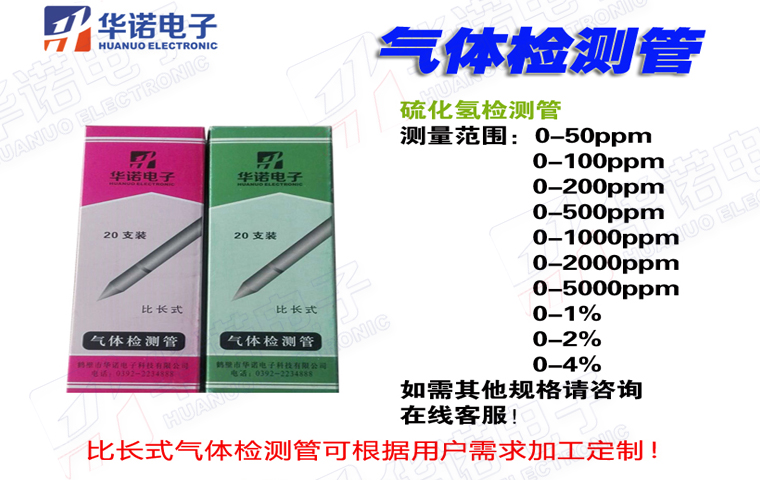

Gas detection tube series

Crushing Sampling Series

Sulfur Meter Series

Calorimeter Series

Industrial analyzer series

Element analyzer series

Coal Ash Fusibility Test Series

Coke Testing Equipment Series

Coal active equipment

Gas detection tube series

Crushing Sampling Series

Without any energy or power supply, the detection tube can be quickly detected. It has the characteristics of simple operation, convenient carrying, and can detect the content of phosphine gas in the air.

(1) Dual advantages: the gas detection tube is actually instrumentalized chemical analysis method, which is a quantitative, qualitative and fixed value detection method, and has the dual advantages of chemical analysis and instrumental analysis.

(2) Good adaptability: There are three kinds of detection tubes, i. e. I, II and III, ranging from zero point to several PPM (10-6) to tens of percent. They have a wide range of applications and provide great convenience for analysis.

(3) Easy to operate: It provides a great convenience for professional inspectors. Operators can test according to the operation method of the operation instructions.

(4) Safety of use: Manual operation when in use, no need for power supply, heat source, in the presence of flammable and explosive gases can be used safely.

(5) The analysis speed is fast: because of the convenient operation, the time needed for each analysis is greatly shortened. Generally, it takes only ten minutes to get the results. The analysis speed is incomparable with any chemical analysis and instrumental method.

(6) High measurement accuracy: In determining the content scale of the detection tube, the field analysis conditions are simulated, and different standard gas calibrations are adopted to overcome the method errors easily brought in in chemical analysis. At the same time, the artificial error is reduced.

Gas detection tube is a tool for rapid determination of harmful gas concentration in air. It fills a certain amount of detective agent in the thin glass tube and fixes it with material, then heates and melts the two ends and closes them. Detecting agents generally use silica gel, activated alumina, glass particles as carriers, which makes the method of measuring pollutant concentration by detecting tube simple and rapid.

Working Principle of Gas Detection Tube

All kinds of gas detection tubes are made by filling a certain amount of detective agent (i.e. indicator powder) in a fixed glass tube with limited length and inner diameter, fixing it with plug, and sealing the two ends of the glass tube. Detecting agent is a kind of substance which can react with the substance to be tested and can change the color of the chemical reagent adsorbed on the surface of solid carrier particles. The choice of chemical reagent and its chemical concentration ratio on the carrier determine the composition and range of the substance in the detection tube.

Application of Gas Detection Tube

All kinds of calibration pipes can be used with CZY-50 gas calibration pipes, such as cylindrical positive pressure sampler.

After washing the sampler with air, take a certain volume of air, cut the two ends of the calibration tube, connect the lower end of the calibration tube (the "0" end of the concentration gauge) to the outlet of the sampler (calibrator), pass through the calibration tube at a uniform speed according to the specified time, and then change the color column (or ring) according to the calibration tube. The upper indicator directly reads the percentage concentration of the measured gas.

Type I: 0.0001-0.012%

Type II: 0.001-0.1%

Type III: 0.01-0.5%

Type IV: 0.5-20 ppm

Note: The longer gas detection tube can be customized according to the user's needs.