Service Hotline

400 8392 001

Service Hotline

400 8392 001

Sulfur Meter Series

Calorimeter Series

Industrial analyzer series

Element analyzer series

Coal Ash Fusibility Test Series

Coke Testing Equipment Series

Coal active equipment

Gas detection tube series

Crushing Sampling Series

Sulfur Meter Series

Calorimeter Series

Industrial analyzer series

Element analyzer series

Coal Ash Fusibility Test Series

Coke Testing Equipment Series

Coal active equipment

Gas detection tube series

Crushing Sampling Series

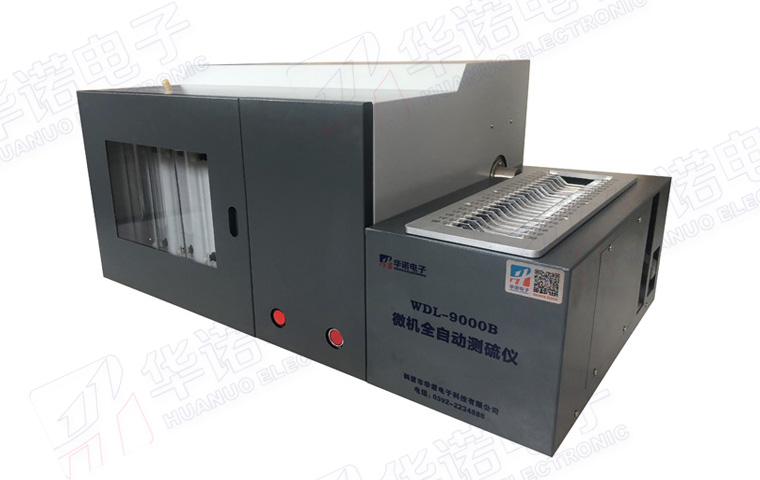

The WDL-9000B microcomputer automatic sulfur analyzer adopts Coulometric titration principle and is suitable for the determination of total sulfur content in coal, coke, petroleum and solid biomass fuels and SO3 content in cement.

Compliance with standards

GB/T 214-2007 "Determination of Total Sulfur in Coal"GB/T 214-2007 "Determination of total sulfur in coal"

GB/T 25214-2010 "Determination of total sulfur in coal by infrared spectroscopy"

GB/T 215-2003 Method for determination of various forms of sulfur in coal

GB/T 387-1990 "Determination of sulfur content of dark petroleum products - Tube furnace method"

ASTM D4239-2012 Standard Test Method for Total Sulfur in Analytical Samples of Coal and Coke: High-temperature Test-Tube Furnace Combustion Method

GB/T 28732-2012 "Solid biomass fuel total sulfur determination method"

ISO 16994-2015 - Determination of sulfur and chlorine in solid biofuels